History Of Shaving cream

Females were advised to save cans of cooking fat, and then deliver all of them to regional butchers just who amassed and delivered unwanted fat to detergent makers. Because pollutants had been inescapable in components gathered therefore haphazardly, the soap makers had to heat up, strain, and reheat the fats—a process both ineffective and costly. However, by the end of this war, installing questions regarding purity and consistency led to the development of the present day, regulated detergent and aesthetic industry.

Females were advised to save cans of cooking fat, and then deliver all of them to regional butchers just who amassed and delivered unwanted fat to detergent makers. Because pollutants had been inescapable in components gathered therefore haphazardly, the soap makers had to heat up, strain, and reheat the fats—a process both ineffective and costly. However, by the end of this war, installing questions regarding purity and consistency led to the development of the present day, regulated detergent and aesthetic industry.

And raising issues concerning the top-notch detergent, World War II contributed into invention of this squirt can. Aerosol bins were first invented through the war as a device for coping with insects carrying malaria alongside diseases. In the beginning assigned toward Secretary of Agriculture, the patent for this "bug bomb" was launched to United states industry after the war. If the first aerosol shaving lotion appeared in 1950, it captured virtually one fifth of this marketplace for shaving arrangements within a short time. Today, aerosol arrangements dominate the shaving cream marketplace.

Recycleables

The aim of any shaving planning would be to damp and soften the hair to-be shaved, cushion the result associated with the shaver, and offer a recurring movie to soothe the skin. This movie should be for the proper pH value: neither extremely alkaline nor excessively acid, it will correspond to the skin's pH level.

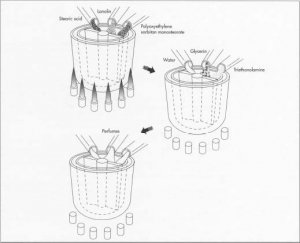

Many makers will have us genuinely believe that the recipes for shaving ointment tend to be very carefully guarded secrets. However, the privacy revolves mostly across the amounts where standard components are utilized, plus the chosen substitutes for couple of what are variable. By-law, components are listed directly on the container, aside from perfumes. Actual dishes are easily within manufacturing chemistry textbooks offered at numerous libraries. A regular meal contains roughly 8.2 per cent stearic acid, 3.7 per cent triethanolamine. 5 percent lanolin, 2 percent glycerin, 6 % polyoxyethylene sorbitan monostearate, and 79.6 % water.

Two significant ingredients in this formula are typical in lots of nowadays's arrangements. Stearic acid is amongst the primary ingredients in soap making, and triethanolamine is a surfactant, or surface-acting agent, which does the task of soap, albeit much better. While one end of a surfactant molecule appeals to dust and oil, one other end appeals to water. Lanolin and polyoxyethylene sorbitan monostearate are both emulsifiers which hold water towards skin, while glycerin, a solvent and an emollient, renders epidermis softer and much more supple.

Typical substitutes for 3rd, fourth, and fifth components in the above list feature laureth 23 and lauryl sulfate (both sudsing and foaming representatives), waxes, cocamides (which clean and help foaming), and lanolin derivatives (emulsifiers). Most components are powdered or flaked, although lanolin, lanolin types, and cocamides are liquids.

The differences between one brand of shaving ointment and another total changes when you look at the proportions of ingredients and in the handling method (much longer or shorter heating times, storage space associated with the finished product, etc), and range of ingredients such as for instance emulsifiers or perfumes. Also important could be the chosen aerosol propellant. Some mixtures contain more than one propellant; most typical are butane, isobutane, and propane. Although wide range of choices for components established fact, the actual combinations of ingredients represent the highest degree of "magic" in modern chemistry.

The Manufacturing

Process

The current manufacture of shaving lotion is a carefully controlled process. Although performed on a sizable scale, its manufacture resembles a laboratory process involving just little quantities of components. There are two main phases into the production process.